Smarter Bioprocess Development with the AMBR 250 Fermenter System

Transforming Bioprocess Development with the AMBR 250 Fermenter System at Scinai BioServices

High-Throughput Fermentation and Process Optimization

At Scinai BioServices, one of the technologies that enables us to accelerate fermentation development is the Sartorius AMBR 250, a highly automated mini-bioreactor system designed for rapid, data-rich microbial and cell-culture process development.

In this blog, we highlight what the AMBR system is, how it works, and why it has become a transformative platform in our CDMO workflows.

What Is the AMBR 250 Fermentor System?

The AMBR 250 (Advanced Micro Fermenter) is a high-throughput, automated mini-bioreactor platform widely used in biotechnology and pharmaceutical R&D. Designed for small working volumes (up to 250 mL), it allows researchers to:

Test multiple fermentation or cell-culture conditions in parallel

Reduce material and reagent use

Generate statistically meaningful data early in development

With the ability to mimic larger bioreactor behavior, AMBR 250 serves as a powerful scale-down model that supports reliable scale-up into pilot and production systems.

How the AMBR 250 Works

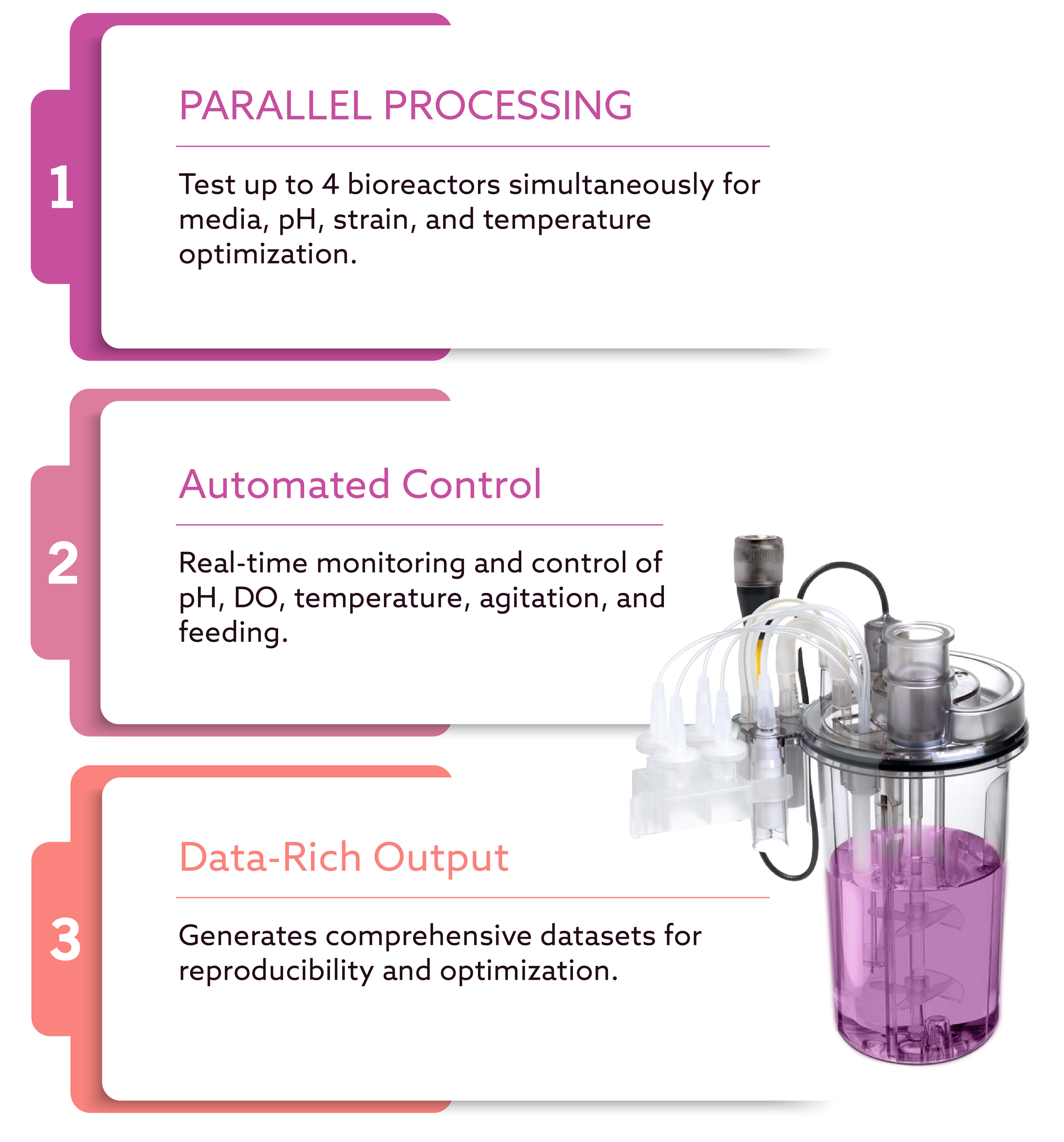

1. High-Throughput Parallel Processing

The system supports up to 4 parallel mini-bioreactors, enabling rapid screening of variables such as:

Media composition

Strain selection

Temperature and pH settings

Feeding strategies

This parallel design dramatically shortens development time compared to conventional 1–10 L fermenters.

2. Automation for Reliability and Reproducibility

AMBR automates critical control parameters:

pH

Dissolved oxygen (DO)

Agitation

Temperature

Feeding strategies

Automation reduces manual intervention, minimizes variability, and ensures smoother, more consistent experimental runs.

3. Integrated Monitoring and Real-Time Control

Built-in sensors continuously track and adjust:

DO

pH

Temperature

Agitation

These feedback control loops allow precise environmental regulation — essential for high-quality process development.

4. Data-Rich Experimentation

AMBR generates a large volume of high-resolution data suitable for:

Statistical analysis

Process characterization

DoE (Design of Experiments) studies

Multivariate optimization

This data-rich environment supports faster, smarter decision-making.

5. Reliable Scale-Down and Predictable Scale-Up

AMBR 250 accurately simulates hydrodynamics and mass transfer characteristics found in larger bioreactors, making it a dependable platform for:

Early-stage feasibility work

Mid-stage optimization

Later-stage scale-up planning

This increases confidence when transferring methods to pilot and production volumes.

Why Scientists Trust the AMBR 250

The AMBR technology is widely valued in the bioprocess community for its:

High-throughput capabilities

Low working volumes and reduced material costs

Automated controls for strong reproducibility

Real-time monitoring and feedback systems

Data-rich outputs ideal for DoE and modeling

Predictive scale-down performance

Reduced labor and faster turnaround

Applicability to both cell culture and microbial fermentation

Together, these features make AMBR one of the most effective platforms for early-stage process development.

Driving Bioprocess Innovation at Scinai

At Scinai BioServices, the AMBR 250 is a central component of our fermentation development workflow. We use it to:

Rapidly evaluate media and strain combinations

Screen pH, temperature, DO, and feeding strategies

Conduct high-quality DoE studies with fewer resources

Build statistically validated, scalable processes

Seamlessly transfer optimized conditions into larger bioreactor for GMP production

By integrating AMBR into our CDMO processes, we save time, reduce costs, and provide our partners with a faster route to scalable, production-ready fermentation systems.

A Word from Zohar Gadri, GMP Development Team Leader

“The AMBR fermentor system allows us to generate high-quality data faster and with far greater consistency — it’s a real game-changer for our CDMO workflows. Its automation, throughput, and reliable scale-down capabilities give us the confidence to optimize quickly and scale predictably.”

Zohar Gadri, R&D Technology Expert & GMP Development Team Leader, Scinai BioServices